Old System:

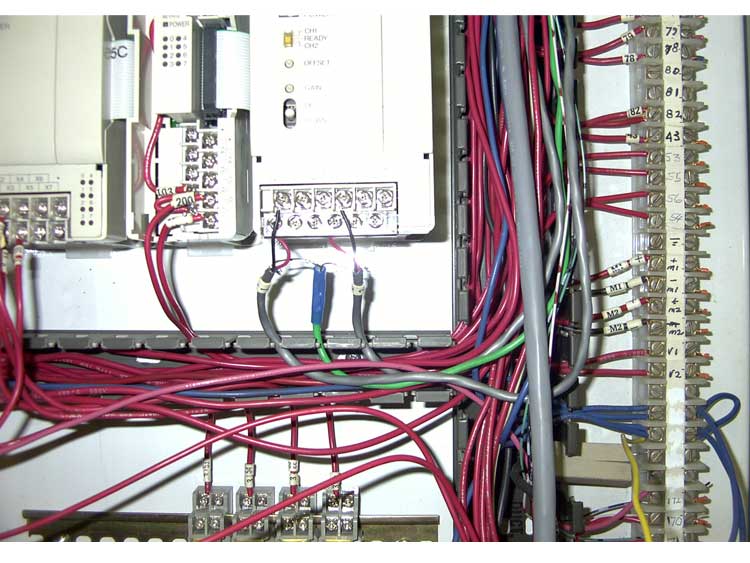

This existing Control System had multiple components altered or replaced over time by sources unknown to Works Global. There had been no documentation to identify what had been changed or why, wiring was not labeled and it was difficult to determine where they originated from or connected to. The work had been performed in a highly disorganized manner. One such remedy included the use of telephone wire to add a diagnostic feature. The existing digital display on the diagnostic system appeared to never have worked properly from original installation, nor ever been corrected. Eventually, the lift would not operate.

Reconstructed System:

- Kept major components and replaced all relays

- Switched out 24 volt AC relays for 24 volt DC relays

- Changed location and installed new style terminal blocks

- Traced all wires, pulled new wires where needed, labeled and documented information

- Installed pilot lamp diagnostic panel, breakers, fuse blocks, three phase monitor

- Removed analog positioning system and replaced with digital positioning system

- Developed new schematics and a User Manual to reflect the current components, wiring, Programmable Logic Controller (PLC), etc.

Original main control system panel

Original main control system panel

Reconstructed control panel

Reconstructed control panel

Close up of control panel BEFORE reconstruction

Close up of control panel BEFORE reconstruction

Close up of control panel AFTER reconstruction

Close up of control panel AFTER reconstruction